Electrical Safety

Electrical Safety

Electrically powered equipment can pose a significant hazard to workers, particularly when mishandled or not maintained. Many electrical devices have high voltage or high-power requirements, carrying even more risk.

Electrical hazards

Primary Hazards

- Electric shock

- Electric fire & explosion

- Electric flash

- Electric burns

Secondary Hazards

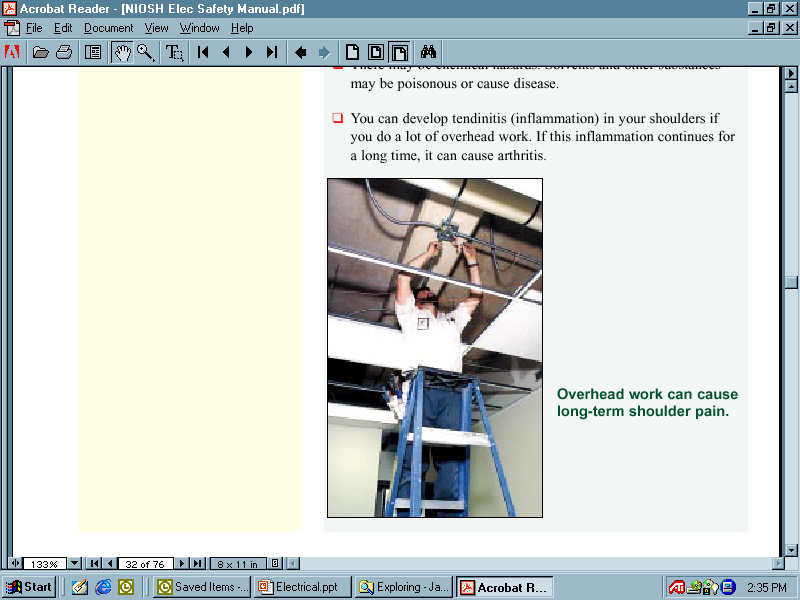

- Person falling from height

- Dropping of tools and object

Electrical Shock Hazard

The major hazards associated with electricity are electrical shock, fire and arc flash. Electrical shock occurs when the body becomes part of the electric circuit, either when an individual comes in contact with both wires of an electrical circuit, one wire of an energized circuit and the ground, or a metallic part that has become energized by contact with an electrical conductor.

The severity and effects of an electrical shock depend on a number of factors, such as the pathway through the body, the amount of current, the length of time of the exposure, and whether the skin is wet or dry. Water is a great conductor of electricity, allowing current to flow more easily in wet conditions and through wet skin.

The effect of the shock may range from a slight tingle to severe burns to cardiac arrest. The chart below shows the general relationship between the degree of injury and amount of current for a 60-cycle hand-to-foot path of one second's duration of shock. While reading this chart, keep in mind that most electrical circuits can provide, under normal conditions, up to 20,000 milliamperes of current flow.

| Sr. No. | Current | Reaction |

|---|---|---|

| 1 | 1 Milliampere | Perception level |

| 2 | 5 Milliamperes | Slight shock felt; not painful but disturbing |

| 3 | 6–30 Milliamperes | Painful shock; “let-go” range |

| 4 | 50–150 Milliamperes | Extreme pain, respiratory arrest, severe muscular contraction |

| 5 | 1000–4,300 Milliamperes | Ventricular fibrillation |

| 6 | 10,000+ Milliamperes | Cardiac arrest, severe burns and probable death |

In addition to the electrical shock hazards, sparks from electrical equipment can serve as an ignition source for flammable or explosive vapors.

Burns:

Burns can result when a person touches electrical wiring or equipment that is energized.

Fire and explosion

Explosions occur when electricity provides a source of ignition for an explosive mixture in the atmosphere.

Falls

Workers who experience a shock on elevated work surfaces such as platforms, ladders or scaffolds.

General safe work practices

- Do not use fire extinguisher on electrical equipment unless it is clearly marked for that purpose. Use sand and blanket instead.

- Do not disconnect a plug by pulling a flexible cable when the switch is on.

- Avoid overloading circuits.

- Make sure switches and insulation are in good condition.

Personal Protective Equipment:

Employees working in areas where there are potential electrical hazards must be provided with and use electrical protective equipment appropriate for the parts of the body to be protected and the work performed. Protective equipment must be maintained in a safe, reliable condition and be periodically inspected.

- Wear safety glasses to avoid eye injury.

- Wear proper foot protection.

- Wear a hard hat.

- Follow the manufacturer’s directions for cleaning/maintaining PPE.

General Protective Equipment and Tools

Insulated tools and handling equipment must be used by employees working near exposed energized conductors or circuit parts if the tools and/or equipment may make contact with the conductors or parts. The insulating material of tools and equipment must be protected where it is subject to damage. Fuse handling equipment, insulated for the circuit voltage, must be used to remove or install fuses when the fuse terminals are energized. All ropes and hand lines used near exposed energized parts must be nonconductive. Protective shields, protective barriers, or insulating material must be used to protect employees from shock, burns, or other electrical related injuries while employees are working near exposed energized parts which might be contacted or where dangerous electric heating or arcing might occur. When normal enclosed live parts are exposed for maintenance or repair, the parts must be guarded to protect unqualified persons from contact with the live parts.

Only qualified workers who have been trained in the avoidance of electrical hazards are permitted to work on or near exposed energized parts. Safety related work practices are employed to prevent electric shock or other injuries resulting from either direct or indirect electrical contact when work is performed near or on equipment or circuits which are or may be energized. The specific safety-related work practices must be consistent with the nature and extent of the associated electrical hazards.

For more assistance and in case of an emergency, please contact 080-2208-2763 or to the main security gate(0802208-2800).

- Back to previous page

- |

-

Page last updated date:17-04-2025 01:03 PM